how does vapor honing work

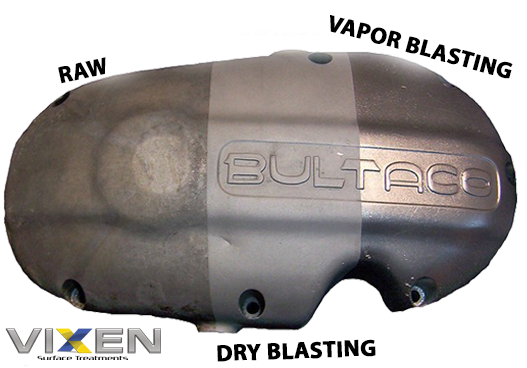

It cleans in areas other methods cant. Using a combination of compressed air and a flow of water borne abrasives this process gives a smooth and fine finish unlike dry blasting it leaves no damage to your parts.

Vapor honing is a low pressure wet blastin g process that safely cleans restores parts leaving a nice finished surface.

. Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface. You also might be asking yourself questions such as. Vapor Hone services- We do this work hourly.

Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion. It is commonly used for cleaning aerospace parts and. Wet Blasting Equipment Vapor Blasting Services.

Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. In order to clean your engine effectively you may have heard of vapor honing. Vapor Honing Technologies Lilhonda Com Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa Vapor Honing Jim S Workshop Vapor Blasting.

Vapor honing is also known as wet blasting it is safe environmentally friendly what vapor honing does is use water and fine high quality abrasives such as glass bead or ceramic powders and air all recycled and reused in our Vapor honing technologys 3630 cabinet. Abrasive selection is made based on desired surface roughness or aesthetically desired finish. Tuttle Motorsports custom automotive design and fabrication automotive restoration and performance upgrades.

Vapor honing is a non-aggressive surface preparation method designed for applications that need smoother finishes. Whatever industry youre inwhether youre an engineer a mechanic or a hobbyistvapor honing is a great technology for you to use. The most common blast media is glass and ceramic amongst a host of other alternatives.

Blast Wash Systems has partnered with Vapor Honing Technologies Force Automation to deliver the next great thing in advanced robotic wet blasting. This process will remove contaminates and. Commonly called vapor blasting or wet blasting.

The process involves blasting off dirt grime and other contaminants using a stream of abrasive gas. Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part. Vixens Aquablast range of wet blasting machines uses the vapor blasting process to simultaneously degrease and blast industrial components of many different shapes and sizes.

The type of media used in this process depends on the required outcome of the cleaning and refinishing process. Combining water and abrasive together forms a slurry which is propelled at the part surface using compressed air. Once you concoct your slurry it goes into the sump at the.

This method removes dirt pollutants tarnish rust and old paint from various surfaces by blending a thin layer of water with small blasting particles. Simple effective. Water abrasive and compressed air are 3 ke.

The vapor blasting process provides the highest quality soft surface finish. But what is it and how does it work. What is Vapor Honing.

What is vapor honing. Vapor Honing or Wet blasting works from high pressurized mixture of a slurry containing water and media. This process can be used on a variety of surfaces including automotive parts furniture and interior cleaning supplies.

How does vapor honing work Tuesday March 1 2022 Edit. Vapor honing does not remove metal its a finish restoration process. Vapor blasting also known as wet blasting or liquid honing is rapidly becoming the number one choice for applications requiring the highest quality of surface finish.

Using a fine glass bead slurry mix with 25-60 psi 37 cfm this is a high volume low pressure process that gets down into the fine areas removing any dirt grime rust or corrosion without removing any metal. Client provides the parts and completed parts are returned in 30-45 days. Restore parts to OEM finish or prep for powder coating and painting with our vapor honing service.

No matter the size or weight of a part we can customize a system to meet your needs whether it be a single or multi part process. How Does Vapor Honing Work. Tuttle Motorsports auto restoration auto.

Vapor Honing Did you know that vapor honing is one of the most advanced technologies you can use for finishing and cleaning surfaces.

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing Services What Is Vapor Honing And Does It Work

Vapor Honing Blasting Superfly Garage

Vapor Blasting What It Is Costs And Shipping

A Simple Introduction To Vapor Honing Issuu

Foxfab Laser And Machine Vapor Honing Wet Blasting Utah Company

What Exactly Is Vapor Honing 5 Things You Should Know

Vapor Honing Bonehead Performance

The Tool You Need For Surface Finishing Vapor Honing Technologies Youtube

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube

What Is Vapor Blasting Answering Your Wet Blasting Faqs

Rust Removal With Vapor Honing Vapor Honing Technologies Youtube

Vapor Honing Technologies Lilhonda Com

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies